| Product Name | Rubber Hose |

| Material | High-Quality Rubber (e.g., EPDM, NBR, SBR) |

| Size | Various Diameters (e.g., 1/4″, 3/8″, 1/2″, etc.) |

| Length | Customizable (e.g., 1m, 2m, 3m, etc.) |

| Wall Thickness | Standard: 3mm to 10mm |

| Reinforcement | Textile Braided, Steel Wire Reinforced |

| Temperature Range | -40°C to +120°C |

| Pressure Rating | Varies (e.g., 0.5 MPa to 3.0 MPa) |

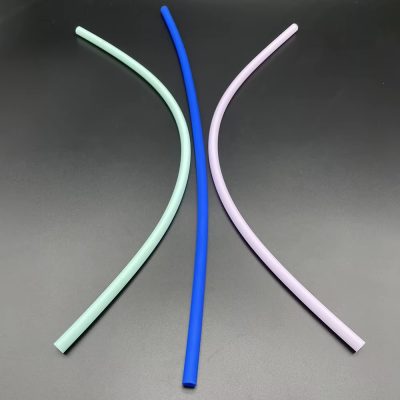

| Color Options | Black, Red, Blue, Custom Colors Available |

| Bend Radius | Customizable Based on Diameter and Application |

| Hardness | Shore A 60 to 90 |

| Inner Surface | Smooth |

| Outer Surface | Smooth or Wrapped |

| Compliance | ISO, SAE, DIN |

| Applications | Automotive, Industrial, Construction, Agriculture |

| UV Resistance | Good |

| Certifications | ISO 9001, ISO 14001 |

Safety and efficiency are critical factors in the design of rubber hoses. These hoses are engineered to prevent leaks and minimize the risk of accidents, ensuring safe operation in high-pressure environments. The rubber material provides excellent insulation, reducing the risk of electrical hazards when used in conjunction with electronic equipment. Moreover, rubber hoses maintain a smooth internal surface, reducing friction and allowing for efficient fluid flow. This combination of safety features and operational efficiency makes rubber hoses a reliable option for various applications.