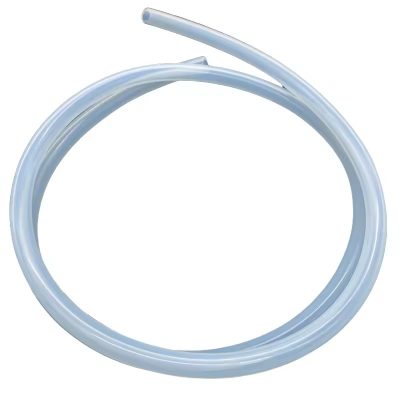

| Product Name | Ptfe Hose |

| Material | Polytetrafluoroethylene (PTFE) |

| Inner Diameter (ID) | 3mm – 50mm |

| Outer Diameter (OD) | 5mm – 60mm |

| Length | Customizable, typically 1m – 30m |

| Wall Thickness | 0.5mm – 3mm |

| Operating Pressure | 20 – 250 PSI (varies with hose type and size) |

| Burst Pressure | Up to 1000 PSI |

| Temperature Range | -70°C to 260°C |

| Flexibility | High flexibility, Bending Radius: 15mm – 300mm |

| Reinforcement | Stainless Steel Braid, Kevlar Braid |

| Color Options | White (Natural), Black, Customizable |

| Outer Covering | Smooth or Corrugated Surface, Anti-static Coating Available |

| Liner Options | Non-stick, Food Grade, Chemical Resistant |

| Standards | SAE 100R14, ISO 9001, FDA (Food Grade) |

| Applications | Chemical Transfer, Food Processing, Pharmaceutical, Aerospace |

| Chemical Resistance | Excellent resistance to almost all chemicals |

| Electrical Conductivity | Available with conductive PTFE for static dissipation |

| Abrasion Resistance | High, especially with external braid |

PTFE hoses are renowned for their exceptional chemical resistance, making them an ideal choice for transferring aggressive chemicals and solvents. The non-reactive nature of PTFE ensures that these hoses can handle almost any chemical, including strong acids, bases, and organic solvents, without degrading or contaminating the fluid. This property makes PTFE hoses indispensable in industries such as chemical processing, pharmaceuticals, and laboratories, where maintaining the purity and integrity of fluids is critical. With PTFE hoses, you can ensure safe and reliable chemical transfer in even the most demanding environments.